Get the free atech 406 external form

Get, Create, Make and Sign

How to edit atech 406 external form online

How to fill out atech 406 external form

How to fill out atech mc 306 form:

Who needs atech mc 306 form:

Video instructions and help with filling out and completing atech 406 external form

Instructions and Help about engineering mc 306 inspection form

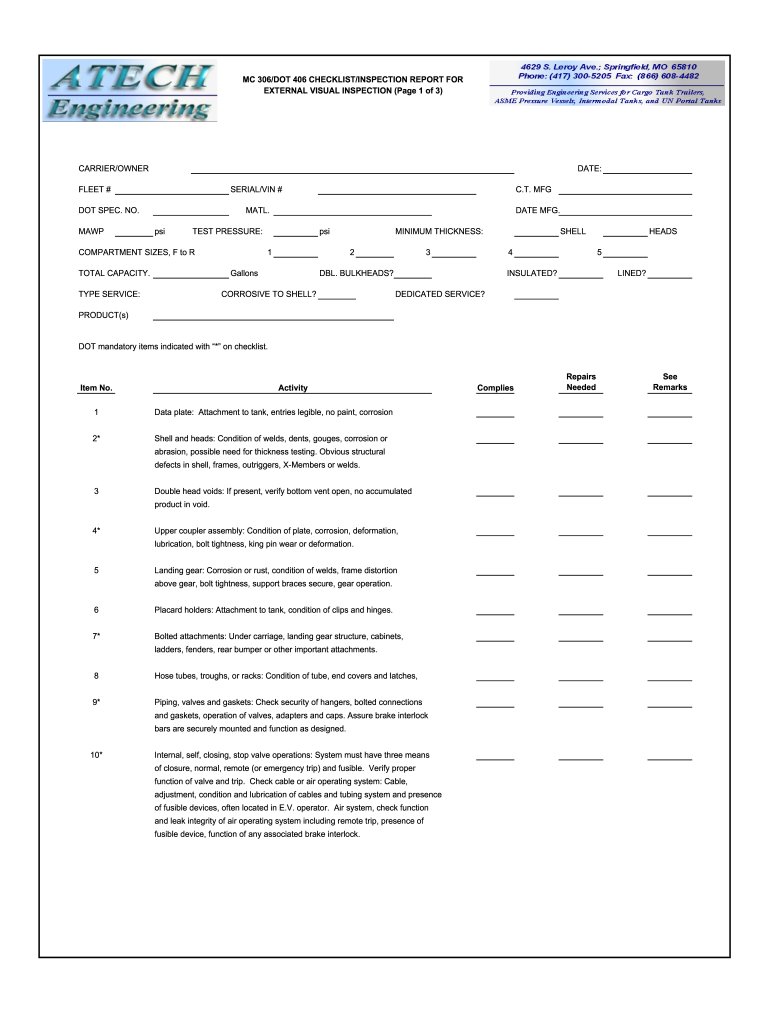

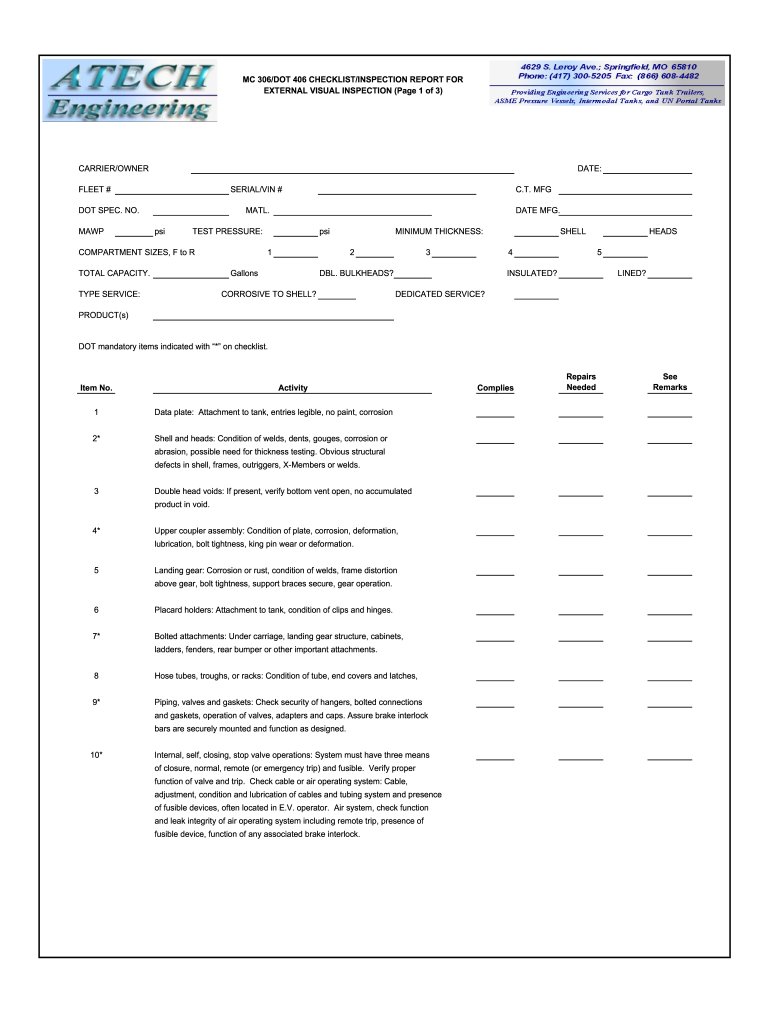

Music the purpose of the EPA method 27 test is to determine the vapor tightness of cargo tank Motor Vehicles designed to haul gasoline and other petroleum-based products it's important for you to understand the basic premise of this test you're responsible for determining if the cargo tank facility is performing the test according to the regulations three parts make up the EPA method 27 test the internal pressure test an internal vapor valve test and the internal vacuum test the pressure and vacuum tests are similar in nature they both require two consecutive runs with final readings being within one-half inch of water pressure of each other the internal vapor valve test is performed one time the most common measurement device used for this test is a water manometer which in its simplest form is an u-shaped tube half filled with water this device indicates the difference between two pressures or between a single pressure and the atmosphere when one side is open to the atmosphere if the u-tube is filled to the halfway point with water and air pressure is exerted on one of the columns the fluid will be displaced some facilities may use alternative measurement devices you need to verify the inspectors know how to calibrate their test equipment for a tank to pass the method 27 internal pressure test it must make two consecutive runs that agree within one half inch of water pressure the average of the two pressure tests must meet the criteria for the capacity of the vessel for instance the average of the two pressure tests performed on a cargo tank with a capacity of 2500 gallons or more must not exceed one inch of water pressure the internal vapor valve test is performed once and the maximum allowable increase in the tanks manifold pressure is 5 inches of water pressure the internal vacuum test must meet the same criteria as the internal pressure test two consecutive runs must agree within one half inch of water the average of the two consecutive test runs must comply with the allowable pressure and vacuum changes for the capacity of the tank each test is performed for a duration of five minutes pressure and vacuum readings are recorded at the beginning and again at the end of the test time existing vapors and the internal temperature of the tank can affect initial test pressure readings be sure to ask if the tanks volatile vapors have been removed and the tanks' temperature allowed to stabilize to the testing environment some shops allow the trailer to sit a full hour inside the facility in order to stabilize the inspector begins the procedure by attaching a static ground connection to the tank he then verifies the tank compartments are empty by draining any remaining liquid into a metal bucket plastic buckets cannot be used for this test because plastic can carry a static to ground charge once the inspector has drained all the compartment valves he opens all the internal valves between the compartments this allows the tank to be pressurized as a...

Fill atech engineering 406 external edit : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

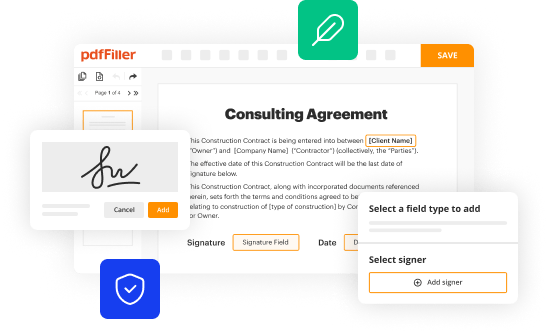

Fill out your atech 406 external form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.